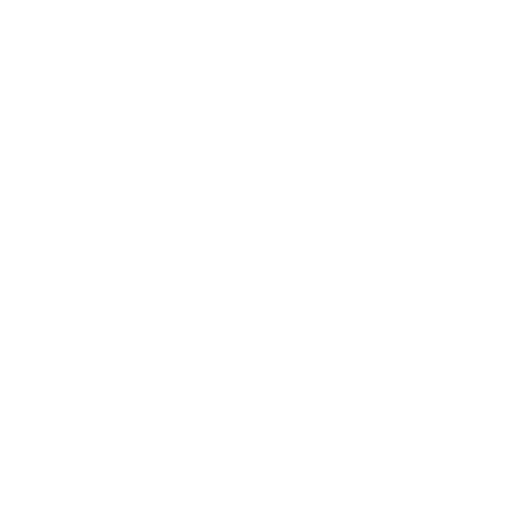

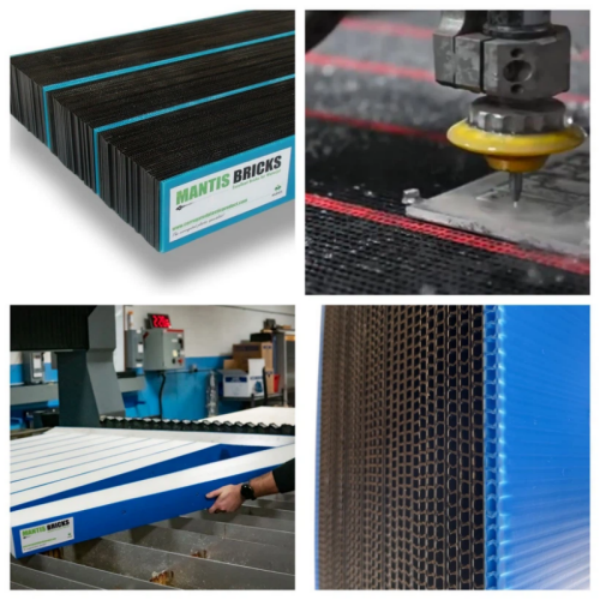

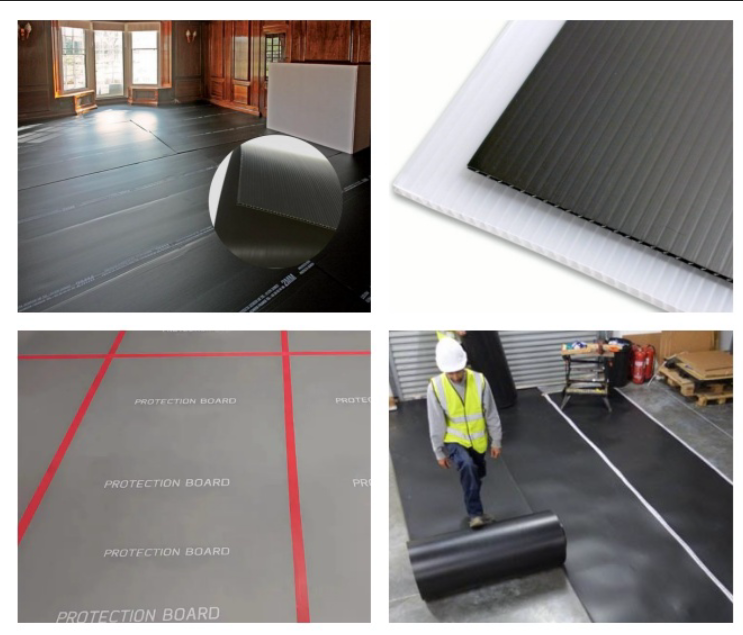

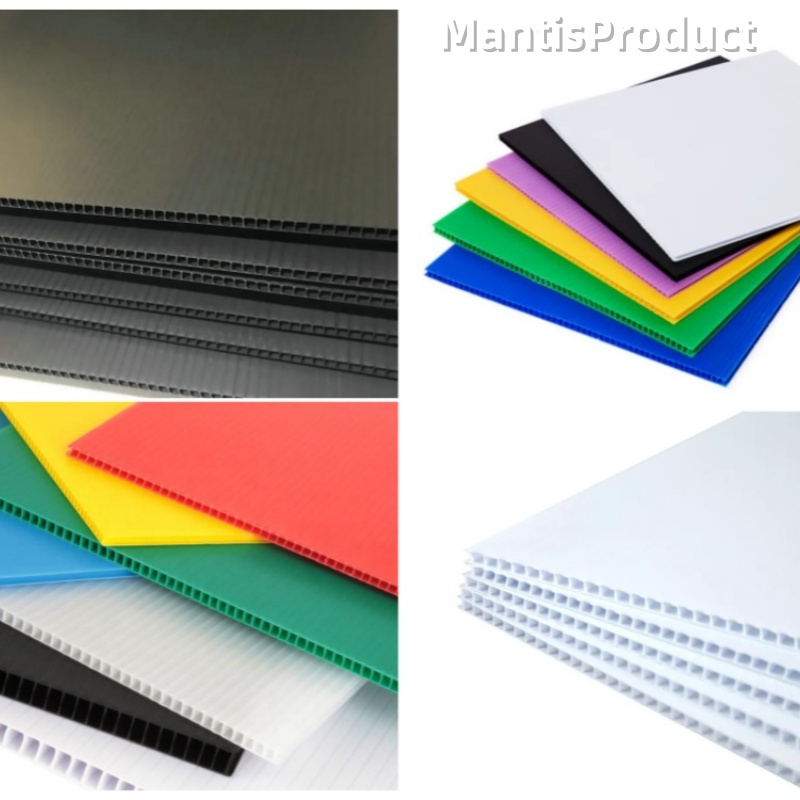

10 years of professionalism manufacturers of high-quality corrugated plastic products

Today, this powerful partnership has enabled Mantis Product to offer a selection of top-notch corrugated plastic sheet items at unbeatable prices and with excellent value-added services for its customers.

1,000

1,000

5,000

5,000

20

20

12

12

Superior Quality

Superior Quality

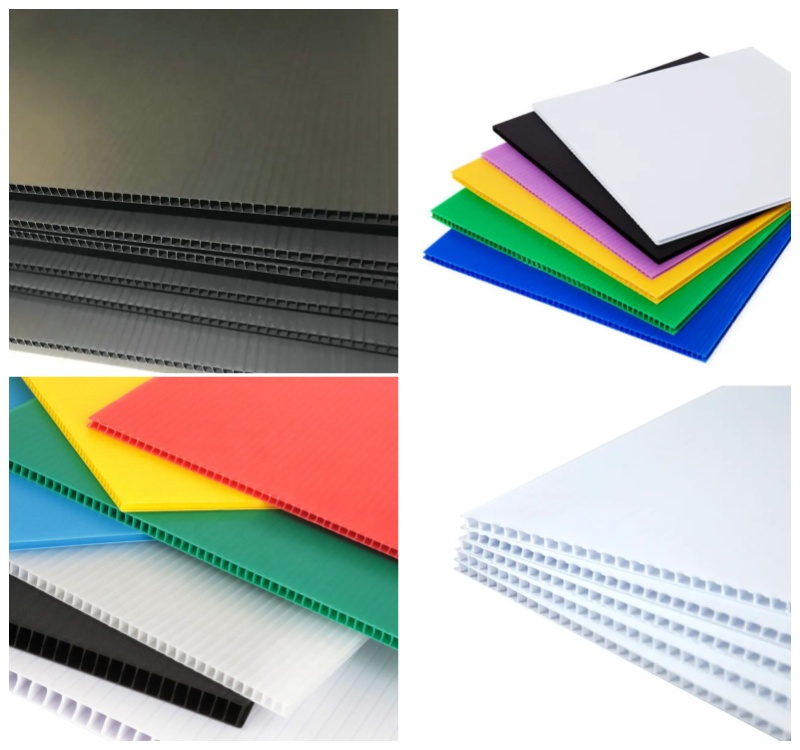

Customization Available

Customization Available

One-stop Service

One-stop Service

Reliable Service

Reliable Service

عربي

عربي Deutsch

Deutsch Français

Français Italia

Italia Portugal

Portugal España

España