Mantis Polypropylene Hollow Sheet (PP Hollow Sheet): Characteristics, Application and Market Prospects

16-07-2025

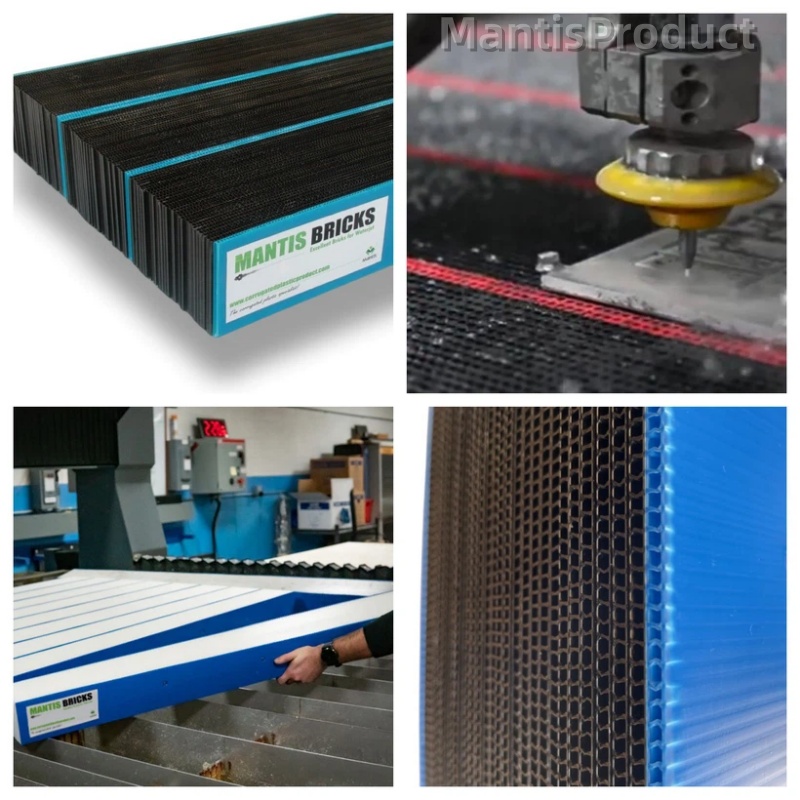

Brick cutting is a common but challenging task in the construction and manufacturing industries. Traditional cutting methods such as sawing or hammering are often inefficient and inaccurate, while waterjet cutting technology (Waterjet Cutting) provides an efficient, accurate and environmentally friendly alternative. This article will explore the principles, advantages, applications and future development trends of waterjet cutting bricks.

Introduction to Waterjet Cutting Technology.Waterjet cutting is a processing technology that uses ultra-high pressure water flow (usually mixed with abrasives) to cut materials. Its working principle is to increase the water pressure to more than 60,000 psi (about 4,137 bar) through a booster system, and spray it through a fine nozzle (about 0.1-0.5mm in diameter) to form a high-speed water flow. For hard materials such as bricks, stones or metals, abrasives such as pomegranate sand are usually added to enhance cutting ability.Advantages of water jet cutting bricks.High precision and complex shape cutting.Water jet cutting can achieve ±0.1mm high precision, which is suitable for brick cutting that requires complex geometric shapes, such as arches, decorative brick carvings, etc.The computer numerical control (CNC) system ensures that the cutting path is executed exactly as designed, reducing human errors.No heat affected zone.Unlike laser or plasma cutting, water jet is a cold cutting technology that does not cause material deformation or thermal stress caused by high temperature, maintaining the structural integrity of the brick.

Environmental protection and safety.No toxic gas or dust is generated during the cutting process, reducing harm to workers’ health and the environment.Wastewater can be filtered and recycled to reduce resource waste.Applicable to a variety of brick materials.Whether it is red bricks, concrete bricks, refractory bricks or glass bricks, water jets can cut efficiently without changing tools.Application Scenarios.Architectural Decoration.Used for customized brick wall patterns, hollow brick carvings and other artistic projects.Historical Building Restoration.Accurately replicate or repair special brick structures in ancient buildings.Industrial Manufacturing.In refractory brick processing, water jets can cut precise sizes for high-temperature equipment linings.Challenges and Future Trends.Despite the significant advantages of water jet cutting technology, there are still some challenges:High equipment cost: The maintenance cost of high-pressure pumps and wear-resistant nozzles is expensive.Cutting speed limit: Compared with traditional sawing, water jets may be slower in thick brick cutting.In the future, with the development of intelligent control systems and higher pressure technology, water jet cutting will further improve efficiency and reduce costs, becoming one of the mainstream cutting solutions in the construction industry.

Water jet brick cutting technology is changing the traditional construction processing method with its high precision, environmental protection and versatility. As technology advances, it will demonstrate its irreplaceable value in more fields and drive the construction industry towards a more efficient and sustainable direction.