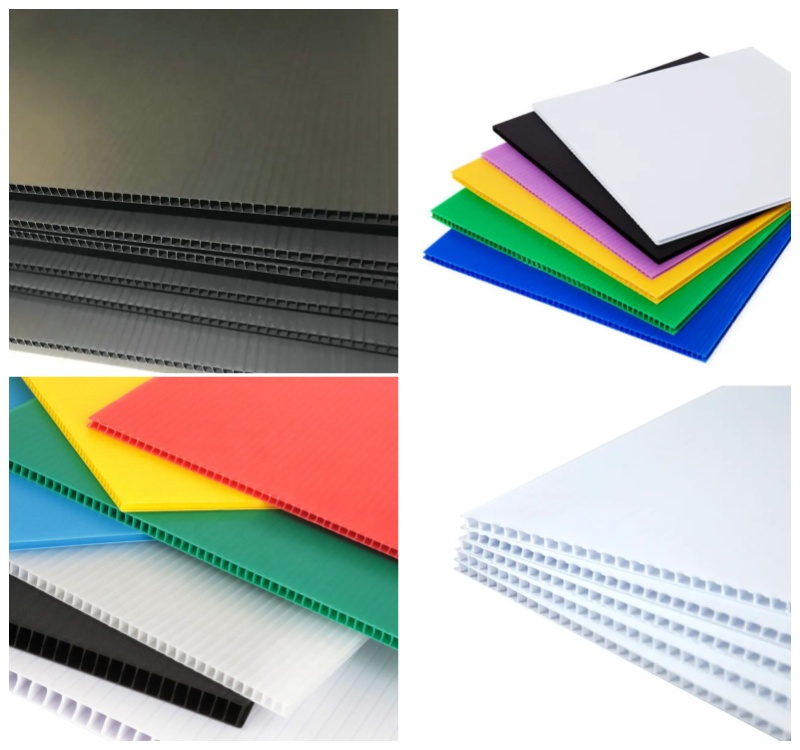

The Versatile Applications of Hollow Plastic Sheets

2025-12-03Hollow plastic sheets have become a pivotal material across industries, thanks to their unique combination of core —lightweight construction, exceptional durability, impact resistance, and corrosion resistance—along with cost-effectiveness and sustainability. These attributes enable them to address diverse operational challenges, making them a go-to solution for businesses seeking reliable and efficient materials.

In the industrial sector, hollow plastic sheets play a critical role in protecting precision components. They are widely customized into trays, dividers, and containers for electronic parts, automotive components, and medical devices. Unlike traditional cardboard packaging, they resist moisture, oil, and dust, ensuring products stay intact during storage and assembly line transfers. For example, electronic manufacturers use these sheets to create compartmentalized trays for circuit boards, preventing scratches and electrostatic damage; their reusable nature also cuts down packaging waste, reducing long-term operational costs for factories.

Within the construction industry, the rigidity of hollow plastic sheets makes them ideal for on-site protection and safety applications. During renovation projects, they act as sturdy floor protectors, shielding finished surfaces like hardwood or tiles from scratches caused by tools and foot traffic. They are also fabricated into safety barriers, scaffolding enclosures, and temporary wall panels for construction sites. Even in harsh weather conditions—such as heavy rain or intense UV exposure—these sheets remain stable without warping, ensuring project continuity and on-site safety for workers.

In logistics and transportation, hollow plastic sheets optimize cargo handling and efficiency. They are transformed into lightweight pallets, foldable containers, and shipping crates, which reduce overall load weight and lower fuel consumption for transportation fleets. Their stackable design maximizes warehouse storage space, while their impact resistance minimizes damage to goods during transit. For cold-chain logistics, these sheets are often combined with insulation materials to maintain stable temperatures, making them suitable for shipping perishable food items or temperature-sensitive pharmaceuticals.

With their ability to adapt to varied industry needs, hollow plastic sheets continue to gain popularity as a versatile, cost-saving, and sustainable material, delivering tangible value to businesses across industrial, construction, and logistics sectors.

عربي

عربي Deutsch

Deutsch Français

Français Italia

Italia Portugal

Portugal España

España